ቡናማ ቀለም የሌለውን ጎማ ለመቁረጥ ልዩ ከፍተኛ ጥራት ያለው የጎማ መመሪያ ጎማ

ቡናማ ቀለም የሌለውን ጎማ ለመቁረጥ ልዩ ከፍተኛ ጥራት ያለው የጎማ መመሪያ ጎማ

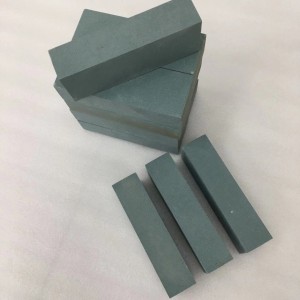

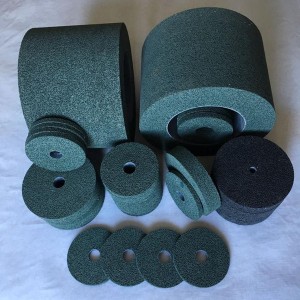

Specification and material of grinding wheel for rubber roller

·Specifications of grinding wheel of rubber roll: our company has many specifications of grinding wheel of rubber roll, such as 300 * 40 * 45, 400 * 40 * 203, 600 * 200 * 305, etc. materials of grinding wheel of rubber roll: generally, its materials include crystalline silicon carbide, black silicon carbide, green silicon carbide, etc. the specific use should be determined according to the customer’s requirements, especially Key points of grinding rubber grinding wheel

·The main point of grinding rubber grinding wheel: when grinding materials, the grinding wheel sometimes pays attention to the properties of abrasive and materials to be ground, so as to play the real role of the grinding wheel. When grinding rubber grinding wheel, some are special, because rubber itself is relatively soft and has certain elasticity, some are also sticky, for example, if you choose not at that time, grinding will overheat and make rubber

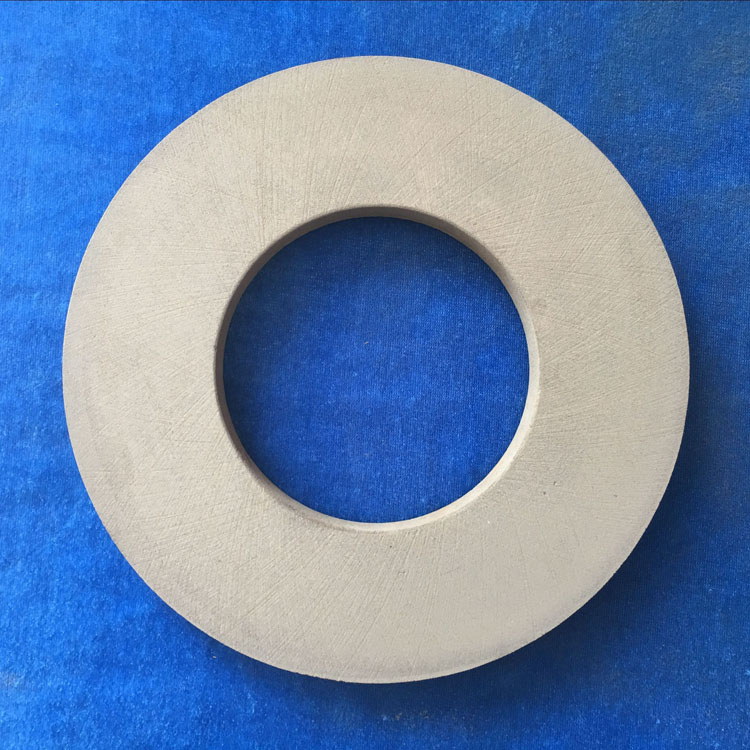

Function of rubber guide wheel

·Function of rubber guide wheel: the rubber guide wheel is mainly used in combination with the centerless grinding wheel on the centerless grinding machine. It can be called the centerless grinding wheel or the guide wheel directly. In the grinding process of the centerless grinding machine, the rubber guide wheel plays the role of guiding, positioning and polishing. Therefore, when selecting the guide wheel, the diameter of the guide wheel is determined by the machine type

Hardness and the hardness of the selected grinding wheel refer to the degree of difficulty for the abrasive grains on the surface of the grinding wheel to fall off under the action of grinding force. The hardness of the grinding wheel is soft, indicating that the abrasive grains of the grinding wheel are easy to fall off, and the hardness of the grinding wheel is hard, indicating that the abrasive grains are difficult to fall off. Hardness of grinding wheel and hardness of abrasive are two different concepts. The same abrasive can be made into grinding wheels with different hardness, which mainly depends on the performance and quantity of the binder as well as the manufacturing process of the grinding wheel. The significant difference between grinding and cutting is that the grinding wheel has “self sharpening”. To choose the hardness of the grinding wheel is actually to choose the self sharpening of the grinding wheel. It is hoped that the sharp grinding particles will not fall off too early, nor will they fall off even if they are blunt.