Wheburring e tsamaeang le ho polisa e nang le wheelchair e sa keneng

Wheburring e tsamaeang le ho polisa e nang le wheelchair e sa keneng

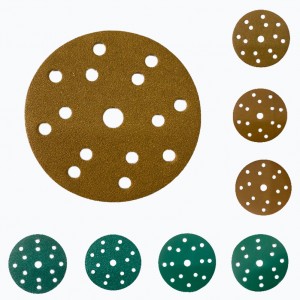

E sebelisetsoa ho hloekisa, ho qhekella, ho qeta, ho polisa le lits'ebetso tse ling, ka ts'ebetso e ntle, e ka hlahisa phello e ntle le e ts'oanang ea ho qeta, ka mela e tiileng.

Bophara ba ts'ebeliso:

E loketse metali eohle, composites le FRP.

Liindasteri tse sebelisitsoeng haholo pele ke: ho taka ka terata ea patsi lihlahisoa tsa lehong, kalafo ea ka tlung pele ho penta le ka mor'a ho penta, ho poma kalafo ea thepa ea ka tlung, ho taka kalafo ea poleiti ea tšepe, ho hohela kalafo ea poleiti ea aluminium le poleiti ea ho ngola, polishing ea fatše. kalafo ea tube ea tšepe le tšepe e sebetsang, e hula kalafo ea polishing ea tšepe e se nang tšepe le tšepe ea koporo, kalafo e hohelang ea mofuta oa nako ea ho shebella, lebanta la ho shebella le tlase, koloi koloi e ntseng e sesa ea likarolo tsa lithuthuthu tsa tšepe, tšepe tse ling, likhalase tsa tšepe, lihlooho tsa bolo ea kolofo, lisepa tsa tšepe, lipompo tsa motlakase, li-radiator, mabone, nylon kamora ho sebetsa, lithupa, lithupa tsa ho tšoasa litlhapi, likarolo tsa kopi, lisebelisoa tsa mohala tsa selefouno, sekoaelo sa tšepe sa MP3, liphanelete tsa tšepe tsa k'homphieutha, joalo-joalo

Nylon wheel is an important branch product of abrasive tools, and it is the grinding product after the strong cutting grinding products such as abrasive belt wheel. Nylon wheel products are mainly composed of nylon fiber net, grinding medium (mineral sand), bonding resin and other main components, in which heat-absorbing additives, fillers, pigments and other additives may be added.

Nylon wheel products are mainly divided into two categories: United wheel and coiled wheel . The laminating wheel is made of industrial white cloth (nylon prebond) coated by roller glue (adhesive and abrasive are included in the glue), stacked and pressed one by one in the oven, baked and solidified, and finally cut. After coating by the same method, the winding wheel is rolled into a rod on a special pipe core and baked and solidified.

Nylon wheel products take the three-dimensional network of nylon web as the mechanical support, and the grinding workpiece has the characteristics of elastic grinding, cold cutting and anti blocking. It is more fine, soft and bright than the same size abrasive belt. Compared with cloth wheel and hemp wheel, the cutting force is stronger and the thread pattern is clearer. Therefore, nylon wheel is often used for grinding wheel belt after sanding, electroplating and mirror surface before sanding. Therefore, nylon wheel is also an important abrasive tool for surface conditioning. The treated lines have good ornamental value and are widely used in the aftertreatment of household hardware products.