Deburring ma faaiilaina uili ma le lalagaina uili faamaapeina

Deburring ma faaiilaina uili ma le lalagaina uili faamaapeina

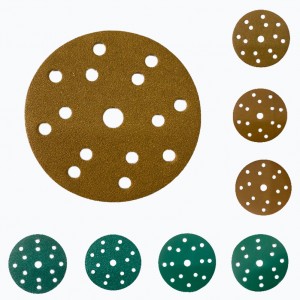

E faʻaaogaina mo le faʻamamaina, deburring, faʻamutaina, faʻamumu ma faʻamamaina ma isi talosaga, ma le lelei aafiaga, e mafai ona maua ai le susulu ma faʻaauau lelei faʻaiuga, ma laina fufusi.

Aotelega o talosaga:

E talafeagai mo metala uma, compites ma FRP.

O alamanuia lautele faʻaaogaina muamua o le: olo o uaea laupapa i mea laupapa, luga togafitiga o meafale i luma vali ma ina ua uma vali, lalagaina olo olo o meafale, tusia le togafitiga o uamea stainless ipu, tusia le togafitiga o alumini ipu ma tusitusiga folasaga, luga polishing togafitiga o uamea stainless faagaau ma pa uamea mea, tusia polishing togafitiga o uamea stainless ma le apamemea uʻamea, olo fofo o le mataitu mataupu, matamata vaega ma le pito i lalo, automobile O le luga olo olo togafitiga o uʻamea uʻamea vaega, isi metala, uamea tioata, tapolo polo ulu, 'au uʻamea, faucets, radiators, moli, nylon ua uma ona vavae, naifi, fagota sasaa, vaega o kopi, ufiufi uamea tapuni uamea, MP3 ufiufi uamea, lima komipiuta uamea vaega, ma isi

Nylon wheel is an important branch product of abrasive tools, and it is the grinding product after the strong cutting grinding products such as abrasive belt wheel. Nylon wheel products are mainly composed of nylon fiber net, grinding medium (mineral sand), bonding resin and other main components, in which heat-absorbing additives, fillers, pigments and other additives may be added.

Nylon wheel products are mainly divided into two categories: United wheel and coiled wheel . The laminating wheel is made of industrial white cloth (nylon prebond) coated by roller glue (adhesive and abrasive are included in the glue), stacked and pressed one by one in the oven, baked and solidified, and finally cut. After coating by the same method, the winding wheel is rolled into a rod on a special pipe core and baked and solidified.

Nylon wheel products take the three-dimensional network of nylon web as the mechanical support, and the grinding workpiece has the characteristics of elastic grinding, cold cutting and anti blocking. It is more fine, soft and bright than the same size abrasive belt. Compared with cloth wheel and hemp wheel, the cutting force is stronger and the thread pattern is clearer. Therefore, nylon wheel is often used for grinding wheel belt after sanding, electroplating and mirror surface before sanding. Therefore, nylon wheel is also an important abrasive tool for surface conditioning. The treated lines have good ornamental value and are widely used in the aftertreatment of household hardware products.