Roue d'ébavurage et de polissage avec roue d'enroulement non tissée

Roue d'ébavurage et de polissage avec roue d'enroulement non tissée

Il est utilisé pour le nettoyage, l'ébavurage, la finition, le polissage et d'autres applications, avec un bon effet, peut produire un effet de finition brillant et cohérent, avec des lignes serrées.

Champ d'application:

Il convient à tous les métaux, composites et FRP.

Les industries largement utilisées auparavant sont: le meulage des bavures de fil de bois dans les produits en bois, le traitement de surface des meubles avant la peinture et après la peinture, le traitement de meulage de flexion des meubles, le traitement d'étirage de la plaque en acier inoxydable, le traitement d'étirage de la plaque d'aluminium et de la plaque d'inscription, le polissage de surface traitement de la pièce à usiner en tube et tige en acier inoxydable, traitement de polissage du dessin de charnière en acier inoxydable et en cuivre, traitement de meulage du boîtier de la montre, du bracelet et du fond de la montre, automobile Le traitement de meulage de surface des pièces métalliques de moto, autres métaux, verres métalliques, têtes de balle de golf, poignées en métal, robinets, radiateurs, lumières, nylon après placage, couteaux, cannes à pêche, pièces de copieur, couvercles en métal pour téléphones portables, couvercles en métal MP3, panneaux métalliques pour ordinateur de poche, etc. La

Nylon wheel is an important branch product of abrasive tools, and it is the grinding product after the strong cutting grinding products such as abrasive belt wheel. Nylon wheel products are mainly composed of nylon fiber net, grinding medium (mineral sand), bonding resin and other main components, in which heat-absorbing additives, fillers, pigments and other additives may be added.

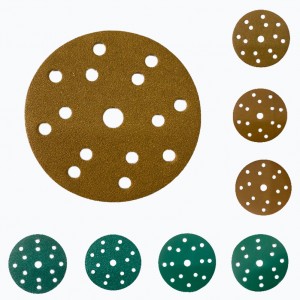

Nylon wheel products are mainly divided into two categories: United wheel and coiled wheel . The laminating wheel is made of industrial white cloth (nylon prebond) coated by roller glue (adhesive and abrasive are included in the glue), stacked and pressed one by one in the oven, baked and solidified, and finally cut. After coating by the same method, the winding wheel is rolled into a rod on a special pipe core and baked and solidified.

Nylon wheel products take the three-dimensional network of nylon web as the mechanical support, and the grinding workpiece has the characteristics of elastic grinding, cold cutting and anti blocking. It is more fine, soft and bright than the same size abrasive belt. Compared with cloth wheel and hemp wheel, the cutting force is stronger and the thread pattern is clearer. Therefore, nylon wheel is often used for grinding wheel belt after sanding, electroplating and mirror surface before sanding. Therefore, nylon wheel is also an important abrasive tool for surface conditioning. The treated lines have good ornamental value and are widely used in the aftertreatment of household hardware products.