Quality control elements of diamond micropowde

When we say the quality is good or not, it is not only depend on the appearance of the particle or the processing way of the particle.We say whether the quality of the product is good or not, and it must be connected with the application. It cannot be said that the quality of green materials is not good, nor can it be said that the quality of high-strength micro-powders is good. It depends on what they are used for.

The right one is the best.

What are the general user requirements?

Generally, there are the following items: workpiece surface quality, processing efficiency, tool life, no scratches, less scratches, chipping, etc. The corresponding inherent characteristics of abrasives include strength, particle size, and particle size distribution, particle shape, presence or absence of large particles, impurity content, impurity type, etc. According to the inherent characteristics of the diamond, there are four main elements for quality control of diamond powder:

1) strength;

2) particle size and particle size distribution;

3) particle shape;

4) purity.

2 Quality inspection method of diamond micropowder

2.1 Strength inspection of diamond powder

The strength of the micropowder is mainly related to the grade of the masterbatch, and the crushing process. Today we will focus on the influence of the grade of the masterbatch on the strength of the micropowder.

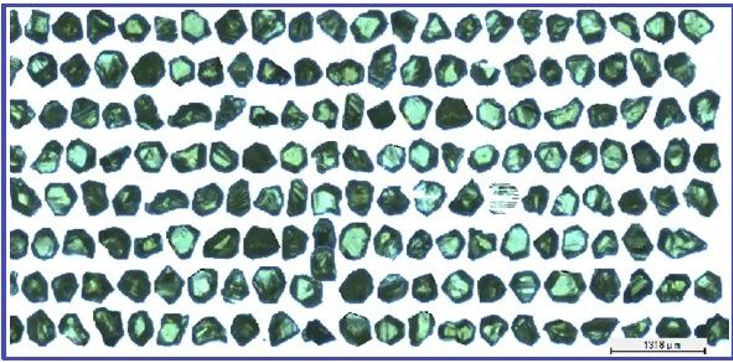

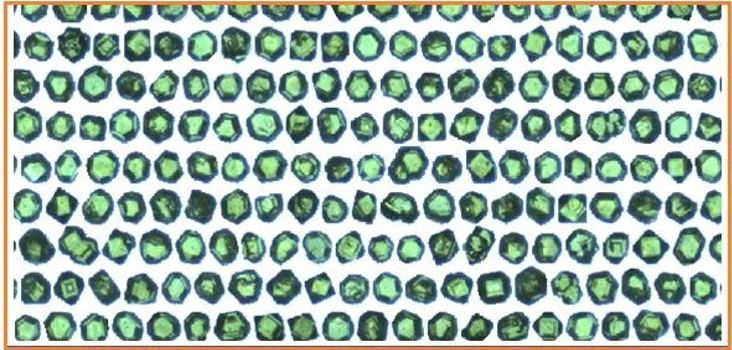

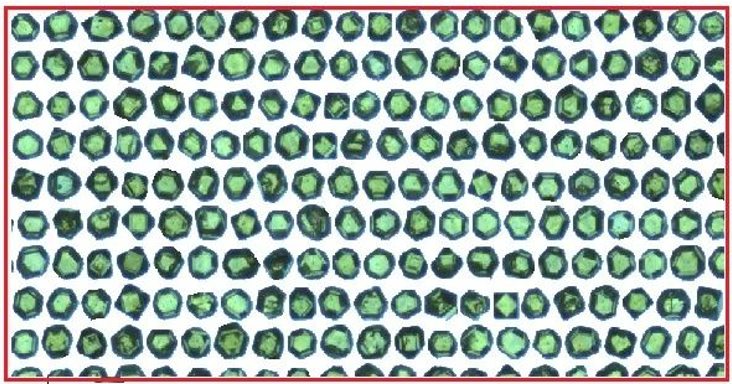

Figure 1 is a comparison of the morphology of different master batches.

Type 1 40/45#

Type 2 40/45#

Type 3 40/45#

It is obvious from it:

Type 1 material has almost no complete six octahedrons crystal form, and there are many internal impurities;

Type 2 material has more six octahedrons, but there are still some incomplete crystal form

Type 3; almost all the materials of type 3 are six octahedrons.

The crashes from type 3 master batches are with more strength than those from type 1 master batches.

Nowadays, micropowder production companies usually use low-tech materials to produce micropowder, that is, type 1 masterbatch. This kind of masterbatch is easier to break. The micropowder produced is usually called "ordinary micropowder" and it is widely used.

Individual applications that require high strength, such as electroplated grinding wheels, some ceramic grinding wheels, etc., need to use "high-strength micropowder". Micropowder manufacturers also have this series of products. As for the so-called "high-strength micropowder" raw material grade.

It is recommended that both the supply and demand Clearly, in order to reduce business disputes and stabilize product quality.

Post time: Dec-03-2021