Հագնվելու անիվ ադամանդի սկավառակով

Հագնվելու անիվ ադամանդի սկավառակով

Դիմում. For grinding and polishing lapidary, glass, ceramics, semiconductors, magnetic materials and etc.

Electroplated grinding wheel is used for grinding,cutting,polishing jade, gemstone, agate, emerald, crystal, ceramic, glass and so on.

Հատկություններ. Uniform electroplated with diamond particles, sharp, wear-resistance, stable, Diamond grits can be customized.

Advantages

High hardness

High compressive strength

Good wear resistance

Less abrasive consumption

Longer life time

Lower temperate in grinding than abrasive tools

Fast removal

Fast grinding or cutting or polishing

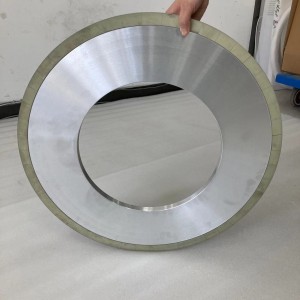

Electroplated Bond Diamond&CBN grinding tools

Electroplated bonds are based on nickel coating on a supporting metal or aluminum body. The cutting and grinding of electroplated bonds is fast but not durable. The cost is lower and the shape is not limited, electroplated wheels are widely used in silicon, semiconductor materials, glass, ceramics and so on.

Characteristics:

Good dress ability and profile ability

Self sharpening

High cutting speeds

High removal productivity

Cubic Boron Nitride(CBN) or Diamond?

CBN has the zinc-blende crystal structure equivalent to diamond, the hardness is a little below diamond.CBN has technological and economic advantages compare to diamond. The hardness of CBN work pieces is as low as 50 HRC but not brittle.

Diamond is the hardest material know now, with a Moh's harness of 10.Compare with CBN,diamond is used for grinding hard but brittle and short-chipping materials, such as tungsten carbide,glass,ceramics,quarz,graphite and so on.

What is concentration?

Concentration of diamond grain is calculated by the diamond weight in the diamond layer. For example,C100% means there is 3.3 carats diamond weight in every 1 cm³ of the diamond layer. Diamond concentration is one of the more important parameters of diamond tools, which affect production efficiency and cost performance. But it doesn't means the higher of concentration, the better of performance.