Sapphire Nesting Drill

Sapphire crystal

Sapphire single crystal is pure aluminum oxide (α-Al2O3), which has excellent thermal conductivity, electrical insulation, light transmittance, chemical stability, high-temperature resistance, high strength, and high hardness. The characteristics of it are window materials for infrared devices, missiles, submarines, satellite space technology, detection and high-power lasers, high-quality optical materials, wear-resistant bearing materials and substrate materials. Sapphire is widely used in the LED industry and electronics and optical industry. Sapphire single crystal has perfect optical uniformity, and there are no defects such as scattering, inclusions and bubbles.

The application of sapphire substrate material accounts for about 75%, of which semiconductor lighting (LED) substrate material accounts for more than 95%. The acquisition of high-performance chips largely depends on the surface processing quality of the sapphire substrate. Sapphire has high hardness and high chemical stability and is a hard, brittle and difficult-to-process material. The processing mainly involves high-precision equipment and high-performance diamond tools. Consumables and matching processing technology.

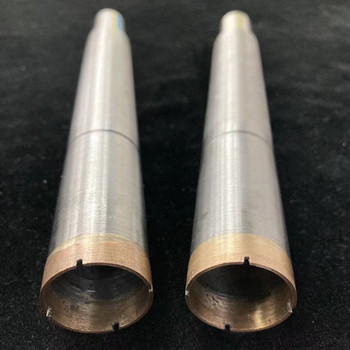

Nesting drill

In the processing of sapphire substrate, the first step is to use a diamond nest drill to dig out the sapphire ingot. The sapphire cutting process is mainly to cut the sapphire crystal with the diamond cutting edge on the top of the nesting drill, and the generated chips are continuously discharged through the chip removal channel of the nesting drill to finally obtain an ingot of the required size.

Post time: Oct-26-2021