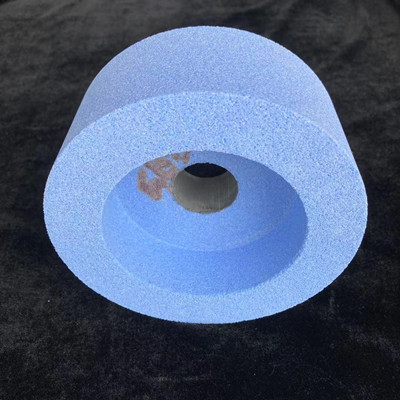

Grinding Wheel Structure

The structure of the grinding wheel and abrasive tool reflects the proportional relationship among abrasive grains, adhesives and pores. The larger the proportion of abrasive particles in the overall grinding wheel, the denser the structure of the grinding wheel and the smaller the pores.

Grinding wheel structure is divided into three levels:

tight, medium and loose.

It is subdivided into 13 structure numbers, from 0-13. The smaller the number, the denser the grinding wheels.

If the general grinding wheel is not marked with the structure number, it means that it is a medium-dense level.

Normally , we divide the structure as below:

Structure No. 0-3, abrasive grains account for more than 55% of the volume of the grinding wheel. The tightly organized grinding wheel is suitable for grinding under gravity. In form grinding or precision grinding, the compact structure of the grinding wheel can maintain the formability of the grinding wheel and obtain a smaller roughness.

Medium structure grinding wheel: structure No. 4-7, abrasive grains account for 54-58% of the volume of the grinding wheel. It is suitable for general hardened steel and sharpening of knives.

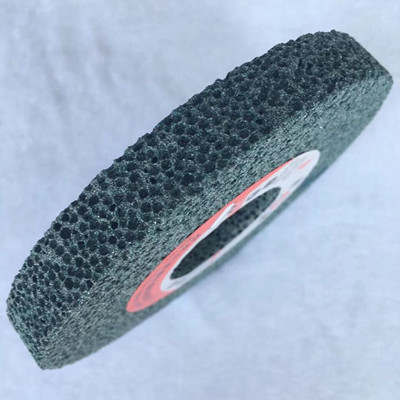

Loose structure grinding wheel: structure No. 8-12, abrasive grains account for 46-38% of the volume of the grinding wheel. The loose structure grinding wheel is not easy to block, and it is used for surface grinding, internal grinding and other grinding processes with large contact areas, as well as grinding heat sensitive materials or thin workpieces.

Post time: Dec-07-2021