2. Structural processing

(1): Cutting type, mainly all kinds of cutting sheets, which are mainly divided into resin cutting sheets and emery cutting sheets according to the material.

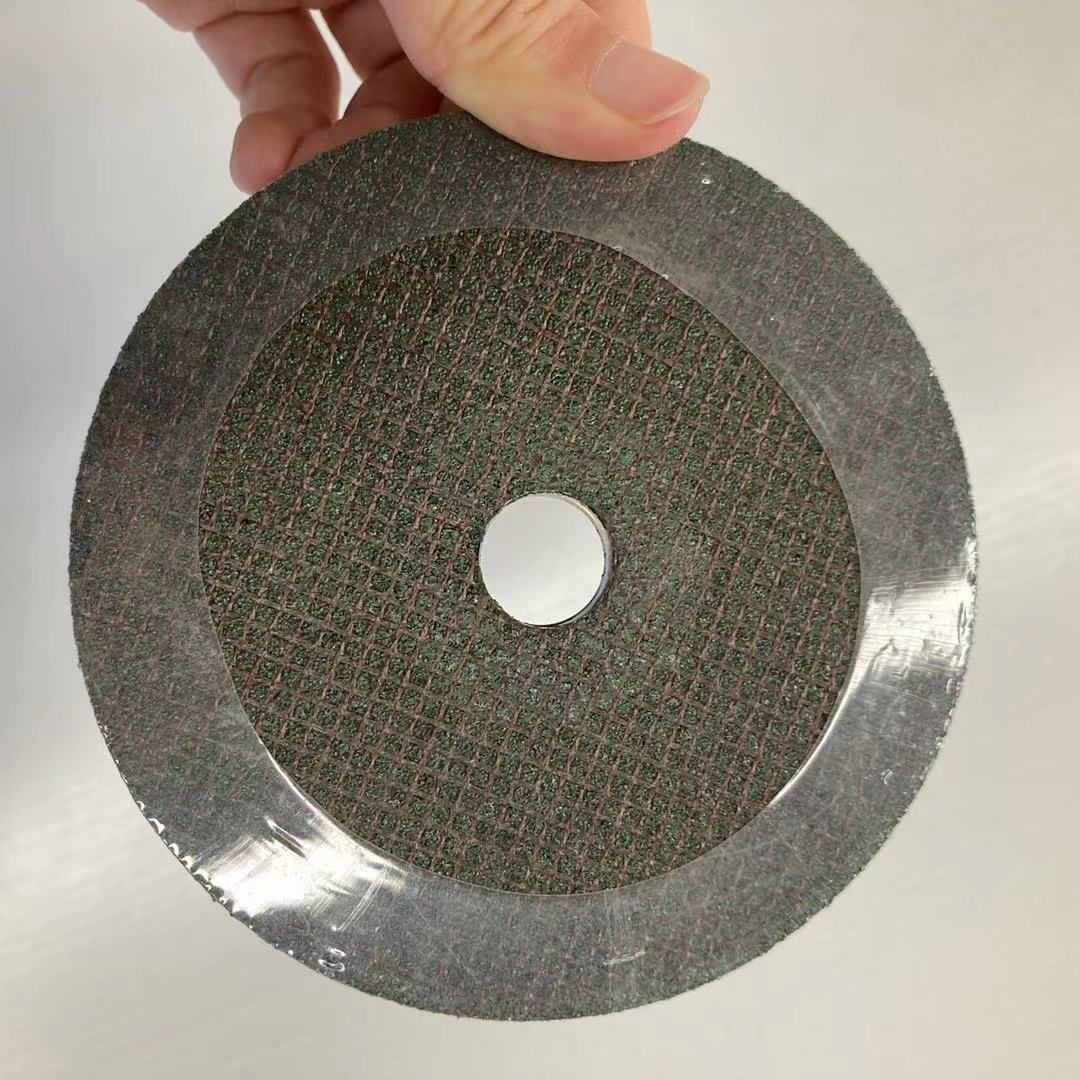

1. Resin cutting discs are divided into non-mesh cutting discs, single mesh cutting discs, and double mesh cutting discs. Angle grinding discs with fiber meshes have higher firmness and are safer to use. It is recommended to use double mesh angle with higher safety factor. Grinding tablets, the price will not be much higher, but it will be much safer!

Resin cutting blade, suitable for cutting metal such as chassis steel plate

The cutting depends on the thickness of the sand on the surface of the cutting blade. The thick cut is fast but the surface of the cut has burrs, and the thin cut is slow but the cut is relatively smooth.

Double mesh cutting blade structure

As can be seen from the picture above,

a. The meshless cutting piece is the most simple, and there is no stainless steel ring buckle.

b. The fiber mesh of the single mesh cutting sheet is generally built-in, and the double mesh is generally exposed on the surface.

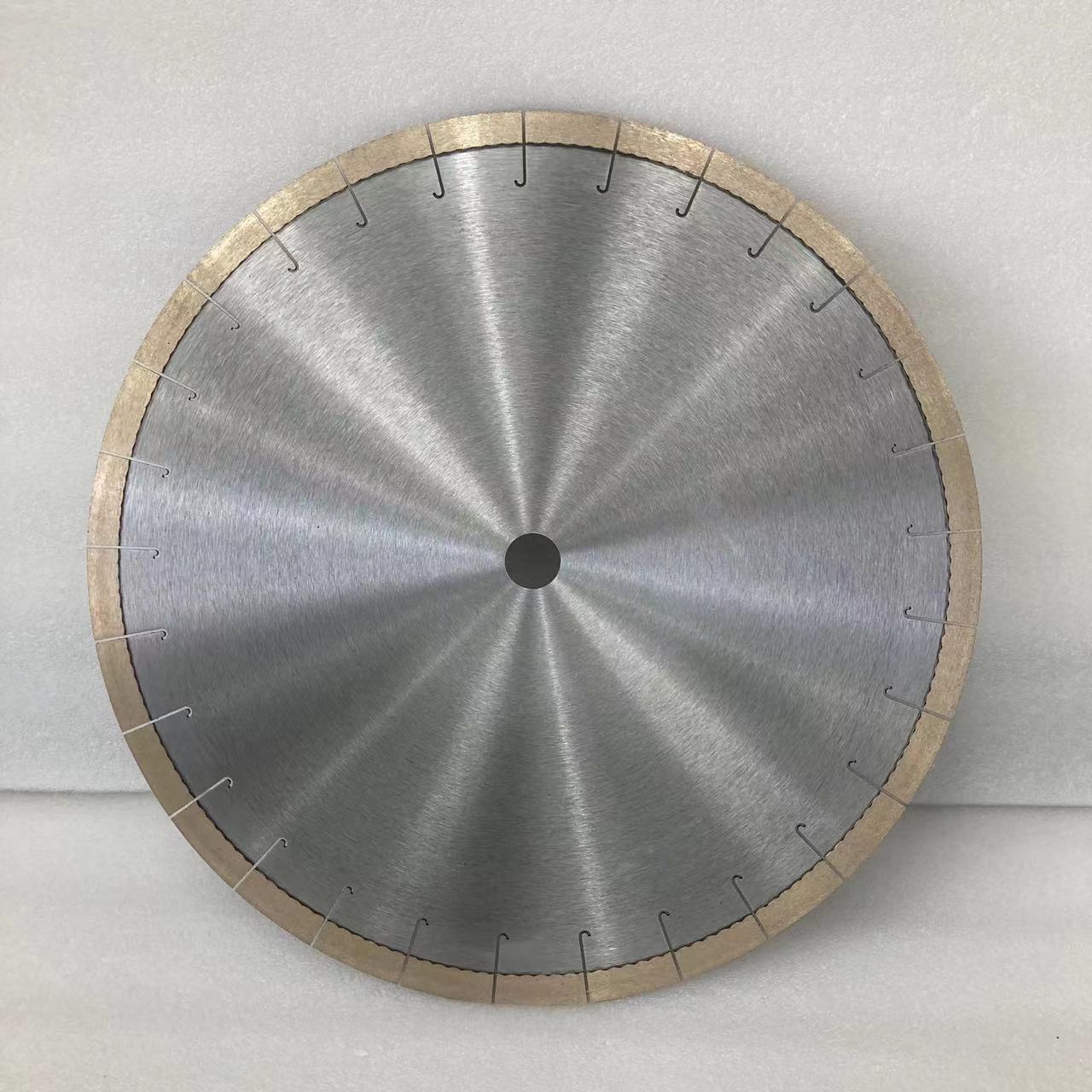

2. Emery cutting blade: mainly for cutting hard alloy and non-metal (ceramic, ceramic tile, glass, marble, jade, etc.) materials (resin cutting blade is mainly used for cutting metal and non-ferrous metal), diamond saw blade can be said to be able to Saw through any object, it is so powerful!

The production of diamond saw blades has the following processes

Sintered diamond saw blade: divided into cold pressing sintering and hot pressing sintering, which are pressed and sintered.

Welded diamond saw blades: divided into three types: high-frequency welding, laser welding and brazing.

High-frequency welding welds the cutter head and the base body together through a high-temperature melting medium.

Laser welding uses a high-temperature laser beam to melt the contact edge of the cutter head and the substrate to form a metallurgical bond.

Brazing is to use flame spraying method (oxygen-acetylene welding gun) to coat the solder alloy (72%Ni, 14.4%Cr, 3.5%Fe, 3.5%Si, 3.35%B, 0.5%O2) on the tool steel substrate, The diamond (uncoated) was arranged on the solder layer, and then induction brazed at 1080° C. under argon protection for 30 seconds to realize the combination of the diamond and the steel substrate.

Electroplated diamond saw blade: the blade powder is attached to the substrate by electroplating.

The structural strength of these three diamond cutting blades decreases in turn, and the same is true for the service life. While sintered saw blades have a longer lifespan, brazed plated saw blades generally have shorter lifespans, but they are also sharper.

Post time: Nov-05-2022