Charactoristics of CBN abrasives

Cubic boron nitride (CBN) is a synthesized superhard material, second only to diamond in hardness, and much higher than ordinary corundum and silicon carbide abrasives.

Its characteristics of high hardness and high toughness make its cutting and grinding ability stronger, sharper, and harder to wear.

The grinding ratio of the CBN grinding wheel can reach 3500-5500, which is a hundred times higher than the ordinary corundum grinding wheel. CBN grinding wheel grinding can obtain high dimensional accuracy and low surface roughness, the machined surface is not easy to produce cracks and burns, and the residual stress is small. CBN grinding wheels significantly improve the fatigue strength of the workpiece. Generally, the lifespan of the workpiece to be ground can belonged by 30-50%.

CBN, as one of the main characteristics of high-performance abrasives, has high compressive strength and good ability to maintain the shape of abrasive grains; therefore, CBN grinding wheels have a long dressing cycle, less dressing amount, and long replacement time;

CBN has good thermal conductivity, and its thermal conductivity can reach tens to hundreds of times that of corundum grinding wheels, so it can quickly remove the grinding heat and reduce the thermal deformation of the workpiece. It is very suitable for grinding materials with low thermal conductivity. Various spraying (welding) materials: nickel-based, iron-based, etc.; wear-resistant cast iron materials: vanadium-titanium cast iron, high-phosphorus cast iron, chilled cast iron, etc.; titanium alloys: such as TC4. Cold cutting can be achieved during cutting or grinding.

Compared with diamond grinding wheel

CBN has the characteristics of high-temperature resistance and good thermal stability. Cubic boron nitride can withstand a high temperature of 1250-1350 degrees Celsius, which is higher than the heat resistance of diamond at 800 degrees Celsius; when grinding and cutting iron materials, there will be no chip sticking phenomenon. It can be used for grinding hardened steel and high vanadium at high speed. Metal materials that are sensitive to grind temperature, such as steel and aluminum high-speed steel, are the most ideal grinding wheels.

CBN also has the characteristics of strong chemical inertness. Cubic boron nitride is not easy to chemically react with iron group elements, so it can replace diamond. For all kinds of high-speed steel, tool steel, die steel, high alloy hardened steel, chromium steel, nickel alloy, powder metallurgy steel and high-temperature alloy, etc. It is very suitable for grinding materials with high hardness and low thermal conductivity.

Therefore, in processing the above-mentioned iron group element materials, the durability is 3-5 times higher than that of diamond grinding wheels.

But cubic boron nitride cannot replace diamond wheels for grinding hard alloys and non-metallic hard materials.

When grinding, only oil-based coolant can be used instead of water-based coolant. Because, under the high temperature of grinding, CBN will undergo a chemical reaction when it encounters alkaline aqueous solution. CBN grinding wheel will decompose in 300℃ alkaline solution, and it can decompose slightly in boiling water. As a result, the crystal shape of abrasive grains will be destroyed.

Types of CBN Grinding Wheel

CBN (cubic boron nitride) grinding wheel refers to a grinding wheel made of cubic boron nitride as an abrasive, and its structure and manufacturing process are the same as those of diamond grinding wheels.

Abrasive + bond constitutes the grinding wheel.

Bonding agent can bond abrasives together to form grinding wheels of various shapes. Different bonding agents can form diamond grinding wheels with different characteristics.

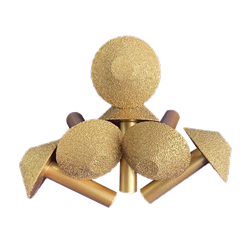

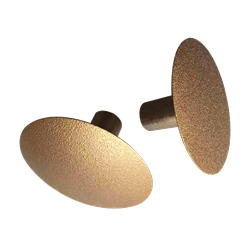

Four series of CBN (cubic boron nitride) grinding wheels have been formed: metal CBN (cubic boron nitride) grinding wheels, resin CBN (cubic boron nitride) grinding wheels, ceramic CBN (cubic boron nitride) grinding wheels and electroplated CBN (cubic boron nitride) grinding wheels Boron nitride) grinding wheel. Brazed CBN grinding wheels are not popular in the market, since of the instability of quality. But We have a stable technique for producing brazed CBN grinding wheels, both brazed CBN cutting disc and brazed CBN grinding wheels. We are happy to offer you professional grinding solutions. Welcome to visit our website:www.hnkm-abrasives.com.

Composition of CBN Grinding Wheels

CBN (cubic boron nitride) grinding wheel is mainly used for grinding, polishing and grinding.

CBN (cubic boron nitride) grinding wheel is generally composed of three parts: working layer, matrix, and transition layer.

Working layer, also known as CBN (cubic boron nitride) layer, is composed of abrasives, bonding agents and fillers, and is the working part of the grinding wheel;

The transition layer, also known as the non-CBN (cubic boron nitride) layer, is composed of bonding agent, metal powder and filler. It is the part that firmly connects the CBN (cubic boron nitride) layer to the substrate. Most of the current grinding wheels have no Use transition layer;

Matrix used to bear the abrasive layer and transition layer. Under the condition of not affecting its rigidity and strength, the base body follows the principle of the lighter, the better.

Generally, metal bond and electroplating bond grinding wheels use steel or metal powder as the matrix; resin bond grinding wheels use aluminum alloy and bakelite as the matrix.

Post time: Sep-09-2021