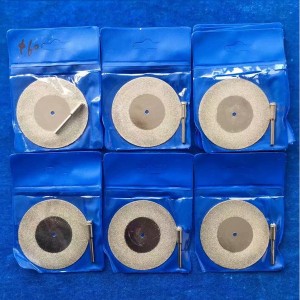

Sintered daemane CBN hlooho e koahetsoeng ka welded shank

Sintered daemane CBN hlooho e koahetsoeng ka welded shank

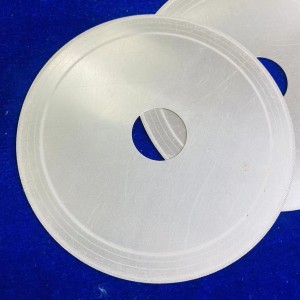

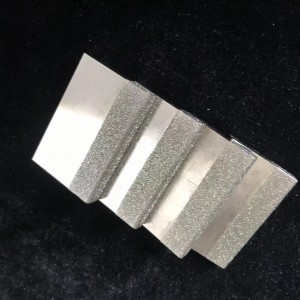

Hlooho ea polasetiki ea daolo ea polasetiki e loketse ho sokolla le ho polisa carbide e kentsoeng: Ceramic zirconia alumina, silicon, lisebelisoa tsa boloi, kristale, gem, khalase ea mahlo, granite, 'mabole, tsebo ea mapolanka le lisebelisoa tse ling, mokhoa oa ho cheka le ho polisa: ho chesoa ka bohale, serethe. ho sesa hantle, ho sesa hantle, ho ts'oaroa seipone se phahameng. CBN polishing grinding grinding grating ea hlooho e loketse ho soahlana le ho polaka tšepe e litšila, joalo ka tšepe e sa tsitsang, tšepe ea lisebelisoa, tšepe ea letsopa, tšepe e nang le tšepe, lebelo le phahameng la tšepe, tšepe ea perelitic grey, lisebelisoa tse phahameng tsa mocheso, lisebelisoa tse thata tsa degree ea hrc40 kapa ka holimo lisebelisoa tsa kalafo ea ho futhumatsa, tshebetso ea daemane le ho checha: polane e bohale, polase e sa hlakoheng hantle, polishing e ntle, polase e phahameng ea khalase. Hlooho ea seha e ka aroloa hore e be hlooho ea li-cutter tsa daemane, hlooho ea moalli ea sehang le hlooho e itšehang ea tšepe. Ts'ebetso ea eona e na le mocheso o phahameng o hanyetsanang le mocheso ebile e bohale. Ke sehlahisoa se hlokahalang bakeng sa ts'ebetso ea thepa, ho e lokisa le ho lokisa majoe. Ka tsoelo-pele ea mahlale le theknoloji, lihlahisoa tsa li-cutter li hlahisoa khafetsa. Diamond bit Diamond cutter hlooho ke 'mele oa mantlha oa daemane e neng e letsoa. Hlooho e khaotsoeng ea daemane e bonoang e entsoe ka daemane le binder ea matrix. Litaemane ke mofuta oa thepa e thata haholo e phethang karolo ea bohlokoa. Matrix binder e bapala karolo ea ho lokisa litaemane. E entsoe ka phofo ea tšepe e le 'ngoe kapa phofo ea tšepe ea tšepe. Sebopeho se fapaneng se bitsoa formula. Ho latela merero e fapaneng, foromo e fapane le daemane. Carbide cutter hlooho Alloy cutter hlooho, eo hape a tsejoang ka hore ke hlooho e thata ea moqapi, ke eona karolo e ka sehloohong ea lisebelisoa tsa ho lokisa lathe. E entsoe ka tungsten, cobalt le magnesium. Litlhoko tse fapaneng ke tse latelang