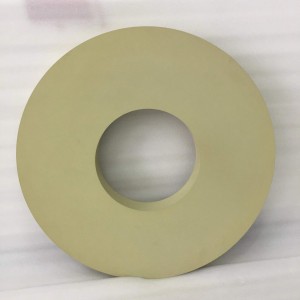

Plane surface Grinding/End Surface Grinding/Resin Bolt Fastening Grinding Wheel/Sharp and durable/Good chip removal/High quality resin grinding wheel/Resin fused alumina grinding wheel

Plane surface Grinding/End Surface Grinding/Resin Bolt Fastening Grinding Wheel/Sharp and durable/Good chip removal/High quality resin grinding wheel/Resin fused alumina grinding wheel

Resin grinding wheel has the characteristics of good elasticity, high strength, low heat resistance, strong self-sharpening, easy to make, short process cycle, etc.

It is widely used for coarse grinding, rough grinding, cutting and free grinding, such as grinding ingots, casting burring, etc.

Resin grinding wheel is a tool in great demand, which is widely used in all kinds of grinding operations.

Such as: surface grinding, cylindrical centerless grinding, slotting and inner grinding.

You should follow the rules as below when you use the resin grinding wheel. Otherwise it will not only affect the grinding quality, but may even cause more serious consequences.

1. Before using the resin grinding wheel, check whether the product is cracked or mute. If so, do not use it;

2. The grinding wheel speed shall not exceed the safe line speed;

3. Do not work with the grinding wheel end face;

4. When the grinding wheel is processing the workpiece, do not use the lever to push and press the workpiece to increase the pressure on the grinding wheel;

5. Professional dressing tools shall be used when dressing grinding wheel, and operators shall wear protective equipment;

6. During grinding, coolant should be used correctly. If the coolant is not needed, dustproof device must be installed;

7. The central hole of the grinding wheel and the central shaft of the grinding wheel must be matched, otherwise they cannot be used;

8. Flanges sandwiched on both sides of resin grinding wheel must have the same shape and size; The diameter should meet the requirements, and there should be grooves on both sides;

9. When installing and fixing the machine, it must be properly tightened. After installation, start the machine to idle for about one minute.

10. The pressure should be uniform when grinding and using. It is strictly prohibited for the grinding wheel to adjust and rotate violently colliding with the workpiece.

Our company, as the leader of precision and ultra precision grinding tools, combines foreign honing technology, advanced technology and high-end equipment in Europe and America, and cooperates with domestic well-known grinding tool research and development institutions. Its high-precision diamond reamer and diamond roller are widely used in the fields of automobile, hydraulic pressure, bearing, machine tool, aerospace and military industry.