Electroplated pob zeb diamond sib tsoo lub log

Electroplated pob zeb diamond sib tsoo lub log

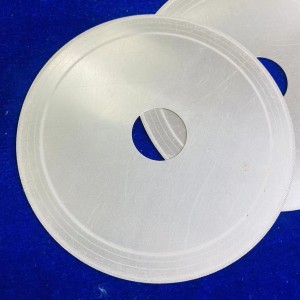

Diamond electroplated double bevel grinding wheel customized non-standard special-shaped back electroplated SDC, CBN grinding wheel cutting piece Cov pob zeb diamond hnyav sib tsoo lub log yog ua los ntawm cov pob zeb zoo, uas muaj qhov ua tau zoo polishing. Tom qab sib tsoo, cov khoom lag luam muaj qhov ua kom zoo nkauj, nws tus kheej zoo dua cov khoom ntiag tug thiab tsis tsim nyog rau kev thaiv. Nws kuj muaj lub siab hardness thiab muaj zog lub sib tsoo. Nws yog tsuas yog siv rau kev sib tsoo zoo, kev sib tsoo ib nrab, riam sib tsoo, polishing thiab lwm yam txheej txheem; kev sib tsoo thiab txiav nyuaj thiab nkig cemented carbide, cov ntaub ntawv tsis yog hlau, ceramics, agate, kho qhov muag iav, cam khwb cia hlau, pob zeb, tungsten steel, hlau siab, iav, cov ntaub ntawv sib nqus, ntsuas cov cuab yeej sib tsoo thiab lwm lub dav hlau sib tsoo, txiav sib tsoo thiab txoj kev ua, sib tsoo, siv lub tshuab tsis muaj kev sib tsoo thiab tshuab ua cov hniav, cov xov iav, xov tshuab xov txiav hom. Electroplated sib tsoo lub log tuaj yeem tuav cov kev ua tau zoo hauv kev sib tsoo raug, grindability thiab kev pab lub neej. Lawv muaj cov lus teb tau zoo hauv ntau lub sijhawm. Qhov zoo ntawm kev sib tsoo lub log: 1. Due to the large protrusion of abrasives, without the influence of binders, the grinding ability is extremely excellent, which can be applied to many different materials processing. 2. Cov qauv duab tsis yooj yim, tuaj yeem tsim cov khoom lag luam qis, txo lub sijhawm luv luv. 3. Generally speaking, because there is only one layer of abrasives with short service life, it is suitable for a small number of diversified production and processing. 4. Yog tias qhov matrix yog hlau, cov lus hais abrasive tuaj yeem raug electroplated ntawm ntau cov duab, yog li nws tuaj yeem siv tsis yog rau cov cuab yeej sib tsoo, tab sis kuj ntxiv rau cov cuab yeej hnav-tiv taus. 5. Nws tuaj yeem rov qab thiab rov qab siv dua (rov ua dua plating) yog tias cov substrate tsis raug rau kev ua haujlwm.