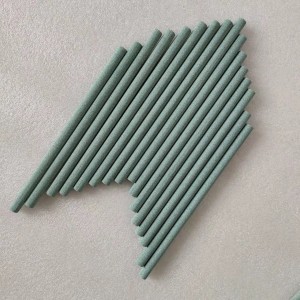

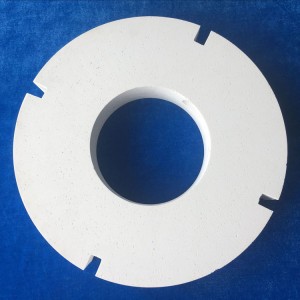

Resin Bond Polishing Grinding Wheel/Black Grinding Wheel/Resin Powder Grinding Wheel/W14 w12 W10 w7 W5 polishing wheel for stainless steel/Graphite Mirror Polishing Wheel

Resin Bond Polishing Grinding Wheel/Black Grinding Wheel/Resin Powder Grinding Wheel/W14 w12 W10 w7 W5 polishing wheel for stainless steel/Graphite Mirror Polishing Wheel

Graphite grinding wheel is also called mirror grinding wheel. This kind of grinding wheel has very fine abrasive grain size. The grinding wheel has the characteristics of compact and uniform structure, which is suitable for precision grinding processes such as polishing.

Graphite grinding wheels are made of organic polymer binders. The grinding wheels have good micro-elasticity. Graphite is used as a lubricating polishing agent to polish the surface of the workpiece. The surface finish can reach Ra0.01-0.02. The old code is 13-14. According to the surface of the workpiece Different fine-grained graphite grinding wheels can be produced with different grit size graphite grinding wheels, coarse-grained graphite grinding wheels GB 600#, and a single side 0.5 wire-1 wire can be lowered, the finest-grained graphite grinding wheel GB 1200#, only the workpiece is polished, It has almost no effect on the size of the workpiece, and can be used for polishing and grinding with the size in place. Due to the different material of the workpiece, the grinding accuracy of the previous process is different, and polishing wheels need to be equipped separately.

Graphite grinding wheels are mainly used for super-finishing, polishing, and mirror grinding processes with a small grinding allowance. The finish can reach Ra 0.04-0.01. This kind of grinding wheel has good elasticity, high precision, low roughness of the workpiece, and can achieve a mirror effect.

Graphite grinding wheels mainly grind some precision machine tool spindles, rolls and other parts, large metal parking belts and coordinate boring machine scribing rulers. In addition, it is suitable for surface polishing of some high-precision, high-value-added parts.

Our company produces ordinary graphite grinding wheels for cylindrical grinding, surface grinding graphite grinding wheels, graphite conductive grinding wheels, centerless graphite grinding wheels, roller graphite grinding wheels, cup-shaped graphite grinding wheels and other special-shaped graphite grinding wheels. We also provide technical services for use,Welcom major manufacturers to try the order.

Our company, as the leader of precision and ultra precision grinding tools, combines foreign honing technology, advanced technology and high-end equipment in Europe and America, and cooperates with domestic well-known grinding tool research and development institutions. Its high-precision diamond reamer and diamond roller are widely used in the fields of automobile, hydraulic pressure, bearing, machine tool, aerospace and military industry.