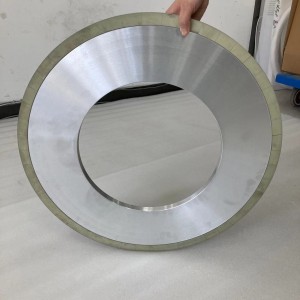

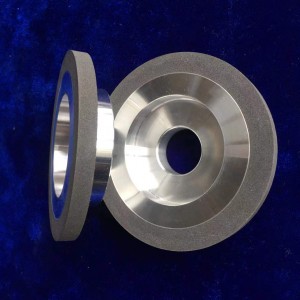

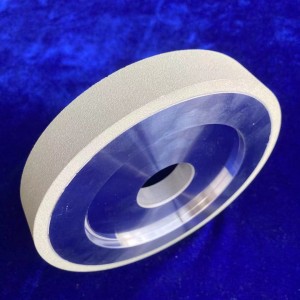

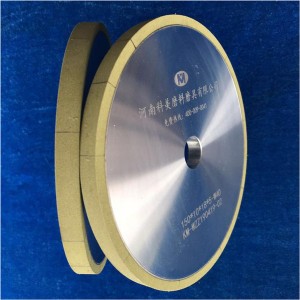

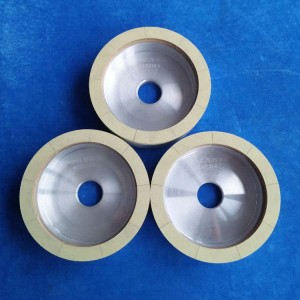

Double Side Grinding Disc Diamond/CBN Grinding Plate 600mm

Double Side Grinding Disc Diamond/CBN Grinding Plate 600mm

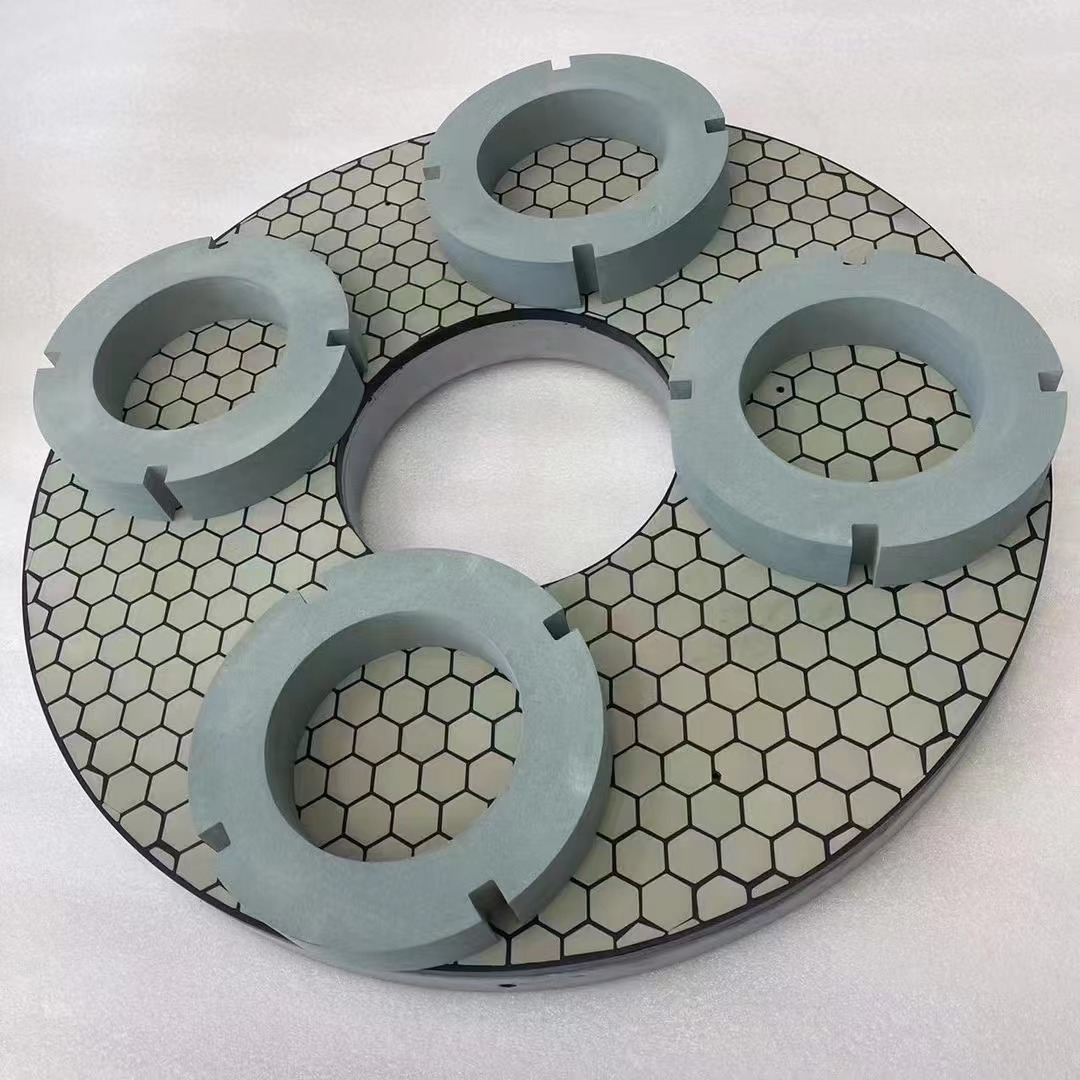

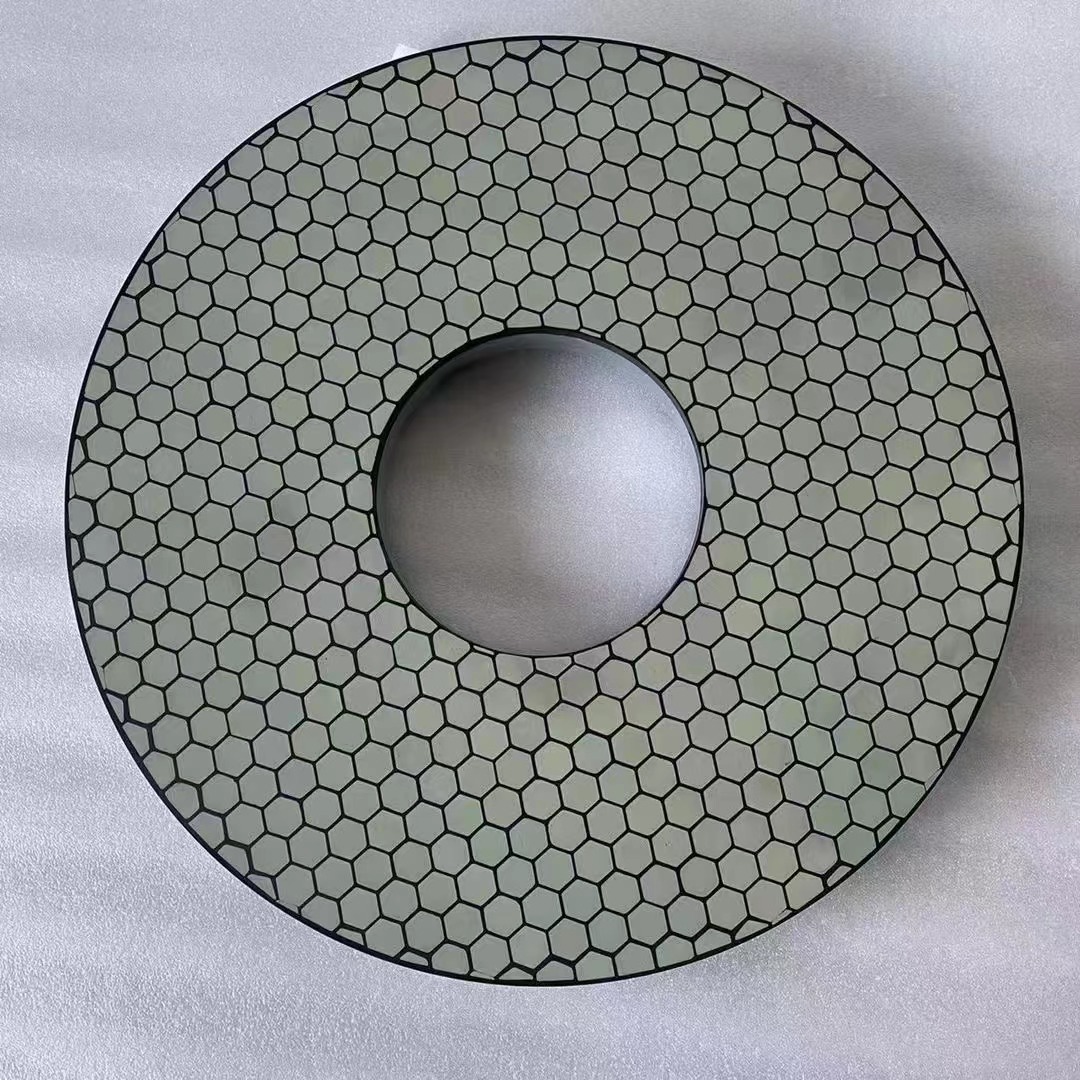

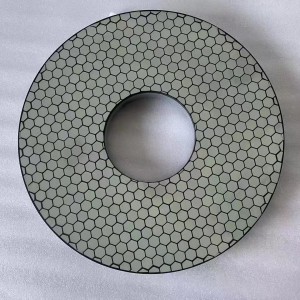

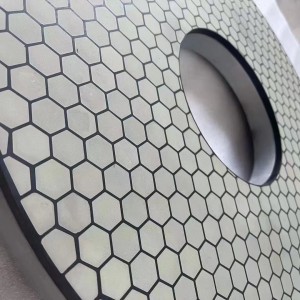

This diamond grinding plate is 600mm diameter. They are used in double set for double face grinding of workpieces. Ceramic bonded diamond or CBN pallets are in hesagon shape, and all working part pallets are attached to the steel core to make it a whole diamond grinding plate.

Double-disc CBN/Diamond Grinding Wheel Grinding Wheel application:

1. The first choice for low-carbon steel. Years of experience have proved that cbn grinding wheels have the best efficiency, with an efficiency increase of about 100% and an economic benefit increase of 200%.

2. For mass production of CNC machine tools, for miniature bearings, air compressor, crankshaft camshaft, high

precision and fine grinding end milling.

3. For work piece with complex surfaces, good grinding wheel edges, pinion cutters, broaches, high-precision gears, modeling, punches, etc. are required.

4. Large precision work piece (machine tool rails, high-precision ball screws, etc.) for fine grinding end mills. These work pieces usually use ordinary abrasives, because high temperature is likely to cause large deformation in grinding, it is best to choose CBN grinding wheels.

5. For heat-resistant steel and high-hardness steel, alloy steel precision parts (above HRC55) and end mills are precision ground. These parts should be worn by general grinding wheels, and the speed should not be too fast, requiring high precision.

6. It is used for special steel tools such as tungsten, molybdenum, vanadium and other high tungsten alloy steels, cobalt alloy steels, special high-speed steel paper-cutting knives, hard-to-depth processing heat-resistant steels, honing and quenching.

7. For high-speed steel containing tungsten, tungsten and molybdenum, especially high-speed steel for vanadium alloy steel and cobalt alloy steel, paper cutter burrs.

8. Precision parts and precision grinding end mills made of stainless steel and high-hardness HRC55 (above) alloy steel.These parts must be ground with ordinary abrasives, which consumes too much grinding and cannot be too fast or passivated to obtain higher accuracy. 9. For titanium alloy CBN grinding, grinding wheel is the best choice.