Factory making cup grinding wheel - Ceramic thread mill manufacturer/White corundum + iron red high toughness thread mill/Helical angle thread grinding wheel – Kemei

Factory making cup grinding wheel - Ceramic thread mill manufacturer/White corundum + iron red high toughness thread mill/Helical angle thread grinding wheel – Kemei

Factory making cup grinding wheel - Ceramic thread mill manufacturer/White corundum + iron red high toughness thread mill/Helical angle thread grinding wheel – Kemei Detail:

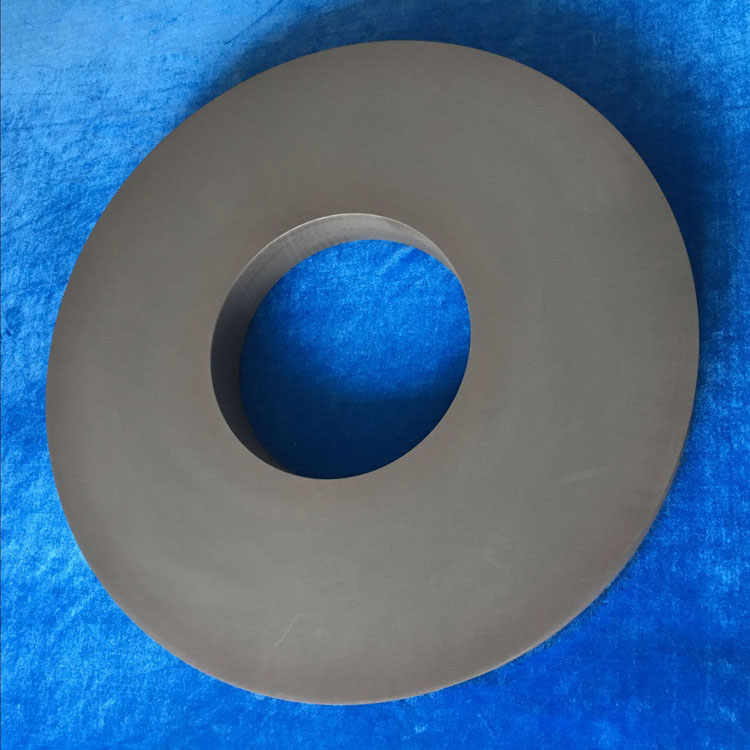

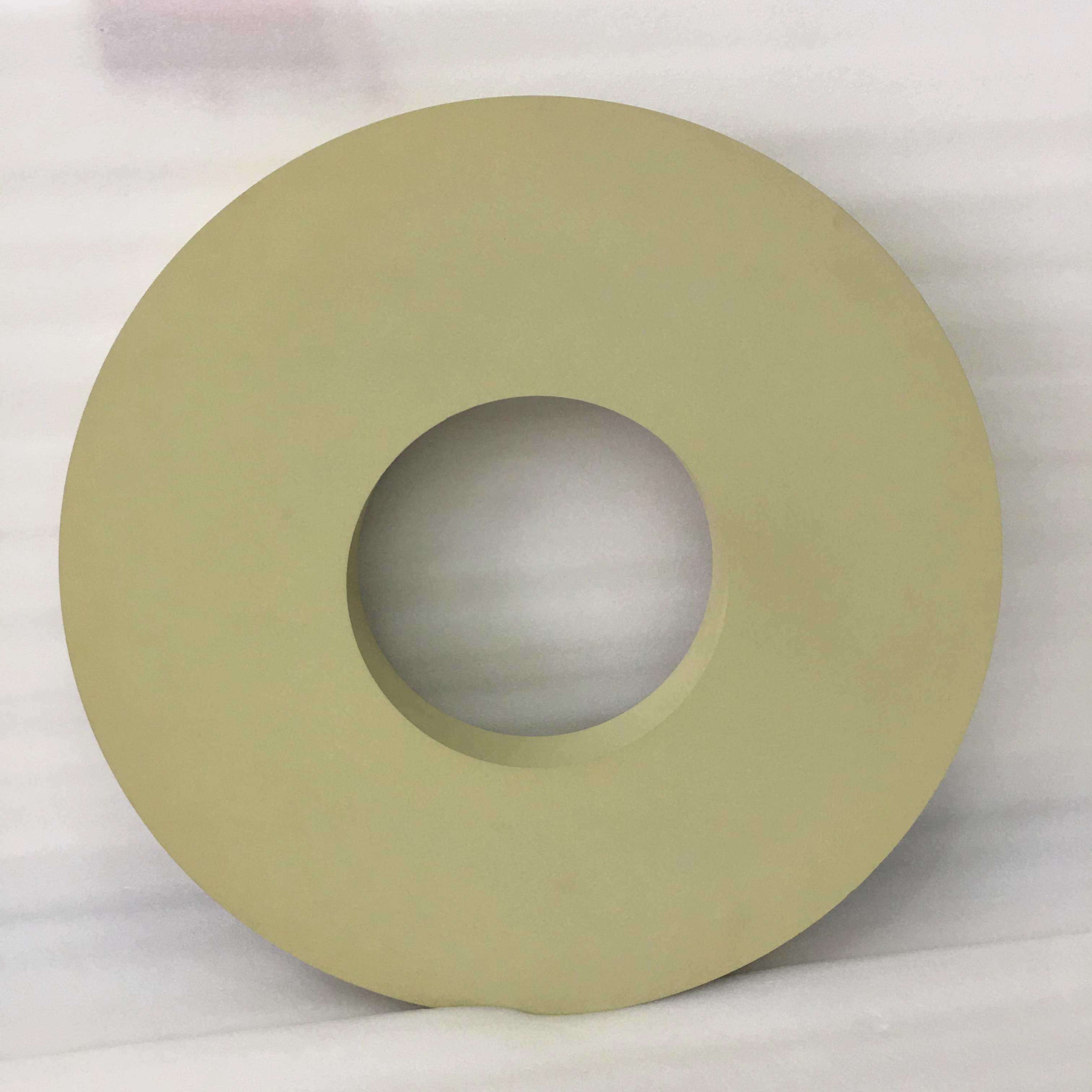

The grinding method of multi-line wheel is suitable for the workpiece with small pitch and the thread length is less than the width of the wheel.

Because the pitch of the workpiece is very small, it is not necessary to make the axis of the grinding wheel tilt a screw Angle during grinding.

Using multi – line grinding wheel to grind thread, high production efficiency, mainly used for mass production. For threads with pitch below 3mm, the threads can be directly ground without premachining.

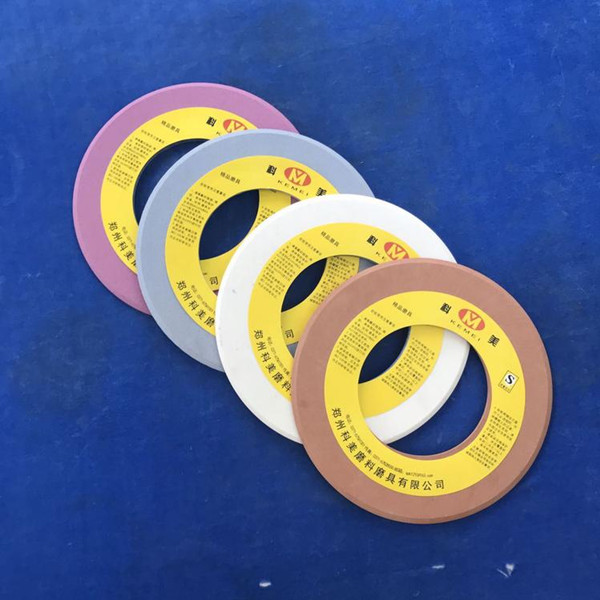

Most grinding wheels use white and chrome corundum abrasives. Single crystal corundum abrasive for grinding stainless steel, high vanadium high speed steel.

Diamond abrasive is used for grinding threaded workpiece of hard alloy and semiconductor materials.

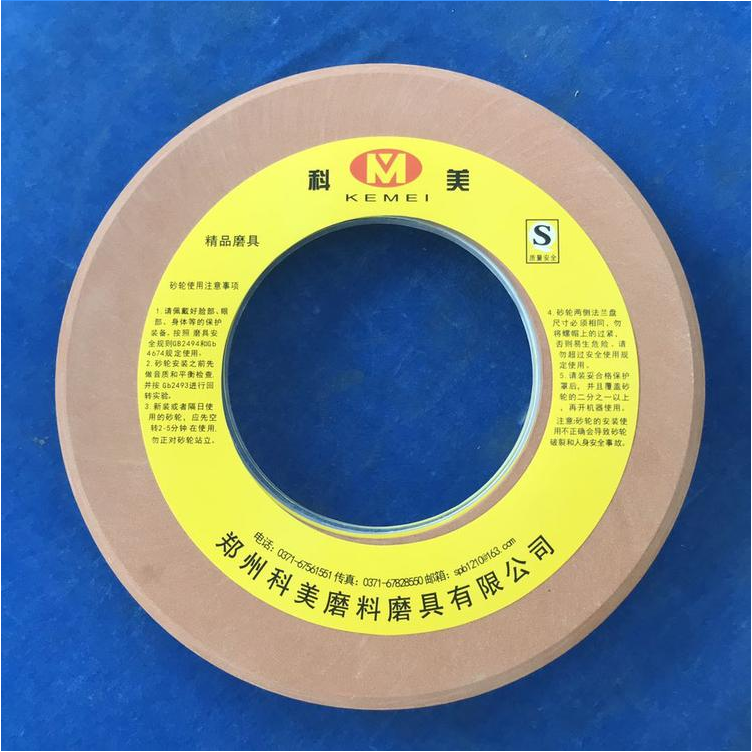

The grain size of grinding wheel is limited by the maximum radius of the thread base of the workpiece. Grinding toughness or ductility is large and sticky of the material, coarse – grained abrasive should be selected; Grinding high hard and brittle materials with tight structure, fine grinding or threaded workpiece with strict shape requirement, grinding wheel hardness is too high to burn the processed surface, too low to maintain the shape of the grinding wheel. When grinding small pitch workpiece, grinding wheel hardness should be higher, grinding metal steel, trapezoidal thread, grinding wheel hardness should be lower. Ceramic binders are used in most cases. High precision workpiece is produced in large quantities and resin binder is used. For grinding wheels with small pitch, proper amount of boron and lead can be added into the ceramic binder to improve the sharpness of grinding wheels.

Our company, as the leader of precision and ultra precision grinding tools, combines foreign honing technology, advanced technology and high-end equipment in Europe and America, and cooperates with domestic well-known grinding tool research and development institutions. Its high-precision diamond reamer and diamond roller are widely used in the fields of automobile, hydraulic pressure, bearing, machine tool, aerospace and military industry.

Product detail pictures:

Related Product Guide:

We emphasize development and introduce new products into the market every year for Factory making cup grinding wheel - Ceramic thread mill manufacturer/White corundum + iron red high toughness thread mill/Helical angle thread grinding wheel – Kemei , The product will supply to all over the world, such as: Brisbane , Irish , Serbia , We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.