Whole Sintering Slicing Disk for PCB Board and Electronic Component

Whole Sintering Slicing Disk for PCB Board and Electronic Component

About the product:

|

Name: |

whole body sintering cutting wheel for semiconductor,Diamond grinding wheel, |

|

Material |

without steel back, whole body diamond working part |

|

Shape |

flat |

|

concentration |

100% |

|

Grit |

Micropowder level |

|

Wheel diameter |

78mm |

|

Hole size |

40mm |

|

Overall thickness |

0.12 |

|

Features |

ultra-thin, only 0.12mm thickness |

|

for precision operation |

|

|

high level processing |

|

|

Application |

|

|

Grinding type |

Wet/dry, Wet use recommended |

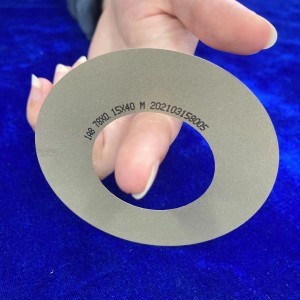

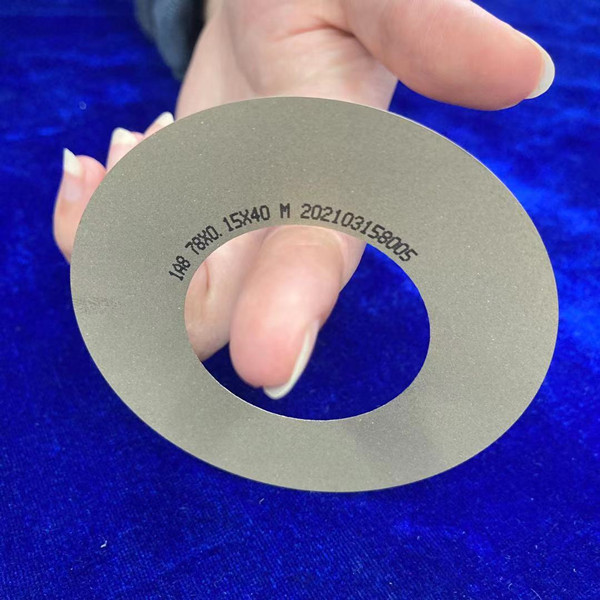

This grinding bit is special made. The ultra-thin slicing wheel is only 0.12mm thickness, with 78mm diameter,40mm hole size.

The slicing disc has whole body sintering diamond coated body, without steel back.

The slicing disk use micro level diamond particle for grinding and cutting;

The ultra-thin cutting wheel is expecially designed for precision processing.

The cutting disc is expecially used on semiconductor field, such as PCB board, electronic components, precision devices.

Characteristics of diamond grinding wheel:

1.The hardness of diamond abrasive determines the main characteristics of diamond grinding wheel, which can grind hard alloy, glass, ceramics and other difficult materials efficiently, and the grinding tool has a long service life.

2.In grinding, the size, shape and morphology of diamond grains change little, which is more suitable for high-precision machining and has high production efficiency. Diamond grinding wheel can meet the requirements of high-efficiency and precision machining at the same time.

3.The sharpened diamond grinding wheel can maintain the micro-edge property of the grinding grains for a long time, and the good cutting performance ensures the less grinding force in the grinding process, thus reducing the grinding power and saving energy.

4.The sharpened diamond grinding wheel can maintain the micro-edge property of the grinding grains for a long time, and the good cutting performance ensures the less grinding force in the grinding process, thus reducing the grinding power and saving energy.

Apply to:precision ceramics, magnetic materials, optical glass, semiconductor materials, stone materials, etc.

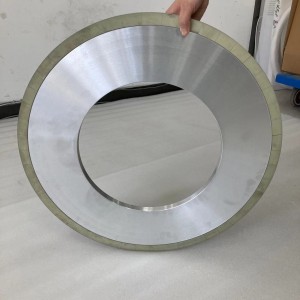

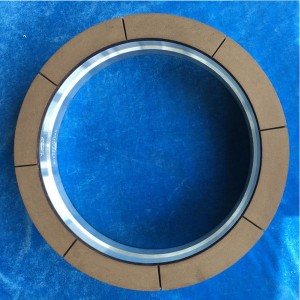

Specialties & Customed Production

As the leader of precision and ultra-precision grinding tools, we can offer you bronze bonded diamond wheels with high quality, high performance, and longer cycle time.

we can make the only grinding wheel for you, based on your applications and special requirement.

If you have special needs on the product, leave us the drawing and your requirement.

If you are not sure which type of grinding wheel to choose, or not sure which grit to use, just tell us and we can provide you professional suggestions and solutions.

What you may concern:

1: Are you a factory?

Yes, we are the producer. Our main products are diamond tools, grinding wheels, cut-off discs, sanding belts, oil stones, mounted points, etc.

2, Can I get free samples?

Yes, within 20USD samples, we can provide for free, but the shipping cost should be covered by the customers.

3, How to confirm the quality?

We have the most experienced technicians and producers. You can send us the technical parameters of the product and we will produce according to your requirements. You can ask for a sample for free. You can have a pilot order, after you confirm the product, then you can release a normal order.

4, What about quality control?

We are using the highest quality components & an efficient manufacturing process. We have the strictest QC process. We are proving a high level of service for customers and distributors. We are trying to nail down the quality complaint to zero. We will make you an enjoyable experience working with us.